Introduction: The Renaissance of Value in Everyday Carry

The year 2026 marks a definitive turning point in the cutlery industry, specifically within the realm of Everyday Carry (EDC). For decades, the market was stratified into two disparate realities: the utilitarian, often disposable "budget" tier, and the precision-engineered, exorbitantly priced "premium" tier. The consumer was forced to choose between a tool they could afford to lose and a tool they could rely on to perform. This dichotomy has effectively collapsed. Through the convergence of advanced manufacturing techniques, novel metallurgical processes, and a shift in design philosophy, the "Budget EDC" category has evolved from a compromise into a class of high-performance tools that challenge the very definition of value.

The modern EDC enthusiast in 2026 is no longer looking for a "cheap" knife; they are seeking the Best Value Knife. They demand the tolerance tightness of aerospace engineering, the edge retention of tool steels, and the ergonomic refinement of custom design—all at a price point that allows for actual, guilt-free usage. In this landscape, one manufacturer has consistently pushed the envelope of what is possible under the $100 mark: CJRB.

As the accessible wing of Artisan Cutlery, CJRB has distinguished itself not merely by undercutting competitors on price, but by out-engineering them on fundamentals. The brand’s strategy relies on two core technological pillars: the proprietary AR-RPM9 spray-formed steel and a standardized ceramic ball bearing pivot system. These innovations have democratized high-performance cutting, bringing "super steel" characteristics and "custom" action to the masses.1

This comprehensive report serves as a definitive guide to the Top 5 Most Reliable Budget EDC Knives for 2026. It is designed not just to list products, but to dissect the underlying science, mechanics, and design philosophies that make these specific tools the EDC Essentials of the modern era. We will explore the physics of spray forming, the tribology of ceramic bearings, and the detailed specifications of the Pyrite, Gobi, Lanky, Tundra, and Ekko models.

Core Content Pillar: The Metallurgical Revolution of AR-RPM9

To understand the reliability of the 2026 CJRB lineup, one must first understand the material that forms its cutting edge. For years, the budget sector relied on ingot steels like 8Cr13MoV or D2. While serviceable, these materials inherently forced a trade-off: D2 offered edge retention but lacked corrosion resistance and ease of sharpening; 8Cr13MoV offered corrosion resistance and ease of sharpening but failed to hold an edge.

CJRB’s solution was to bypass the traditional trade-offs by utilizing a manufacturing process previously reserved for high-end aerospace components and premium tooling: Spray Forming.

The Physics of Spray Forming vs. Traditional Ingot Casting

Traditional steelmaking involves melting the alloy components—iron, carbon, chromium, vanadium, molybdenum—in a crucible and pouring the molten liquid into a large mold (ingot) to cool. The critical flaw in this process is the cooling rate. As a massive ingot cools, it does so slowly and unevenly.

During this slow solidification, the elements within the steel begin to segregate. Carbon and alloying elements seek each other out, forming carbides—hard crystal structures that give the steel its "bite" and wear resistance. However, in slow-cooling ingot steel, these carbides drift and clump together, creating a heterogeneous microstructure.3

- The Consequence of Clumping: The steel matrix becomes inconsistent. Areas with large carbide clumps are hard but brittle, prone to chipping or snapping under stress. Areas void of carbides are soft and weak, leading to rapid edge dulling.

The Spray Forming Solution: AR-RPM9 is not poured; it is atomized. In the spray forming process (often associated with the Osprey process), the molten alloy is ejected through a nozzle where it is blasted by high-velocity jets of inert gas (typically nitrogen). This obliterates the stream into millions of microscopic droplets.2

- Rapid Solidification: Because the droplets are so small, they possess a high surface-area-to-volume ratio. They cool at a rate of thousands of degrees per second. This rapid freezing locks the alloy's chemistry in place instantly.

- Carbide Suspension: There is simply no time for the carbides to drift or clump. They are frozen in a uniform dispersion throughout the steel matrix.

- Billet Formation: These semi-solid droplets impact a collection substrate, building up a dense, porosity-free billet that retains this fine, uniform microstructure.4

The AR-RPM9 Advantage: Bridging the Gap

This process results in a steel that behaves like a premium Particle Metallurgy (PM) steel but incurs a fraction of the manufacturing cost. The microstructure of AR-RPM9 allows it to occupy a unique position in the 2026 steel chart, often described as the "Goldilocks" material for EDC.3

1. Optimization for Corrosion Resistance

D2 tool steel, long the king of budget edge retention, is notorious for rusting. It is a "semi-stainless" at best. AR-RPM9 utilizes its high chromium content (approx 18%) much more efficiently. Because the chromium is evenly distributed rather than tied up in massive carbide clumps, more free chromium is available to form the passive oxide layer that prevents rust. This makes AR-RPM9 a true stainless steel, capable of withstanding sweat, humidity, and food acids without pitting.3

2. Exceptional Toughness and Stability

The fine grain structure eliminates the structural weak points found in ingot steels. When a blade made of traditional D2 impacts a hard staple or bone, the stress creates a fracture that travels easily along the boundaries of large carbides, causing a chip. In AR-RPM9, the fine, sandy texture of the microstructure arrests these micro-cracks. This toughness allows for thinner blade geometries—CJRB often grinds their blades down to 0.11" or thinner—without sacrificing durability.7

3. The "Sticky Sharp" Edge and Maintainability

Perhaps the most tangible benefit for the end-user is sharpenability. Sharpening a steel with large, blocky carbides (like D2 or S90V) is akin to trying to sharpen a concrete sidewalk; the hard rocks resist the abrasive. Sharpening AR-RPM9 is like sharpening a block of dense clay or sandstone. The fine carbides abrade evenly, allowing the edge to take a polished, razor-like apex with minimal effort. It responds aggressively to stropping, allowing users to maintain a hair-popping edge indefinitely without removing significant material.3

| Feature | D2 (Traditional) | AR-RPM9 (Spray Formed) | 14C28N (Ingot) |

|---|---|---|---|

| Microstructure | Coarse, segregated | Fine, uniform | Fine (due to nitrogen) |

| Corrosion Resistance | Low (Semi-Stainless) | High (Stainless) | High (Stainless) |

| Toughness | Low to Moderate | High | Very High |

| Sharpenability | Difficult | Easy | Very Easy |

| Edge Retention | High | High (Comparable to D2) | Moderate |

Data synthesized from metallurgical analysis and performance reviews.3

Core Content Pillar: The Mechanics of "Action"

In the lexicon of modern knife enthusiasts, "Action" refers to the tactile experience of deploying and closing the blade. It is the friction (or lack thereof), the acoustic feedback, and the mechanical snap that indicates quality. A knife with poor action feels like a broken tool; a knife with great action feels like a precision instrument.

CJRB has standardized a Ceramic Ball Bearing pivot system across their budget line, a feature that was essentially nonexistent in the sub-$50 category a decade ago.12

The Tribology of Ceramic Bearings

Friction is the enemy of action. In older knives, blades rotated on phosphor bronze or Teflon washers. While durable, these washers rely on sliding friction. They require a "break-in" period and regular lubrication to remain smooth.

CJRB utilizes a caged bearing system. The blade tang does not slide against a washer; it rolls on top of tiny spherical balls.

- Why Ceramic? Most budget manufacturers use steel bearings. Steel is adequate, but it is softer than the hardened blade steel and susceptible to corrosion. If moisture enters the pivot, steel bearings can rust, seizing the action.

- The Ceramic Superiority: Ceramic (typically Silicon Nitride or Zirconium Dioxide) is significantly harder than steel and chemically inert. It cannot rust. Furthermore, because the ceramic balls are harder than the steel raceways (washers) they roll on, they essentially "polish" the track every time the knife is opened. This means the action of a CJRB knife theoretically improves with use, becoming smoother and "glassier" over time.13

The "Drop Shut" Phenomenon

The combination of AR-RPM9’s density and the low friction coefficient of the ceramic bearings creates what enthusiasts call "Drop Shut" action. When the lock is disengaged (especially on button locks like the Pyrite), the blade falls closed under its own weight, accelerating smoothly into the handle. This provides a high "fidget factor"—the satisfying, repetitive manipulation of the knife that serves as a stress reliever for many users.2

Ergonomics and the "Premium Feel"

Beyond the pivot, CJRB invests in ergonomic refinement. Budget knives often suffer from "hot spots"—sharp edges on the handle scales, lock bar, or clip that dig into the hand during use.

- Chamfering: CJRB aggressively chamfers (rounds) the edges of their G10 and steel handles. This contoured shaping ensures the knife fills the palm comfortably without biting into the skin.15

- Acoustic Tuning: The geometry of the lock interface is tuned to produce a distinct, metallic "thwack" upon deployment. This acoustic feedback confirms the lock has engaged securely, adding to the perceived quality and safety of the tool.16

Product Showcase: The Top 5 Reliable Models

The following analysis details the five models that best exemplify the convergence of AR-RPM9 steel and premium action. These selections cover the spectrum of EDC needs, from the office environment to the wilderness.

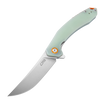

1. The Universal Standard: CJRB Pyrite Series

The CJRB Pyrite has ascended to become the definitive "everyman's knife" of the 2020s. It is the flagship vessel for the AR-RPM9/Button Lock combination, designed to be the perfect size for 90% of daily tasks.2

- Blade: The Pyrite features a 3.11-inch drop point blade. The "Drop Point" is the most versatile blade shape in history, offering a robust tip for piercing and a generous belly for slicing. The high flat grind ensures the blade is thin behind the edge, maximizing the slicing potential of the AR-RPM9 steel.18

- Locking Mechanism: It utilizes a Button Lock. Unlike liner locks, which require placing a thumb in the path of the closing blade, the button lock is disengaged by pressing a plunge lock on the side of the handle. This allows the blade to swing freely on the ceramic bearings, keeping fingers safe and enabling rapid deployment via the thumb stud or by swinging the knife.19

-

Variations: The Pyrite is not a single knife but a platform.

- The Original: Steel handles for heft and durability.

- Pyrite-Light: Features FRN (Fiberglass Reinforced Nylon) handles, reducing weight and cost for a true "beater" EDC.20

- Pyrite-Alt: Features a Wharncliffe blade shape, optimizing the tool for draw cuts (opening boxes) where the tip needs to engage material instantly.1

2. The Aggressive Slicer: CJRB Gobi

- Blade: The Gobi sports a 3.5-inch Upswept (or Trailing Point) blade. By curving the tip upward, the design creates a massive amount of "belly." This curvature increases the linear length of the cutting edge without increasing the overall size of the knife.

- Handle Ergonomics: The handle features a dramatic arc that mirrors the blade. This forces the hand into a locked, secure grip. The scales are heavily contoured G10 with a CNC-milled texture pattern, providing high traction even in wet or oily conditions.22

- Deployment: The Gobi is a Flipper. A tab protrudes from the back of the blade; when pressed, it overcomes the detent and the blade flies open on the ceramic bearings. The flipper tab then acts as a finger guard, protecting the hand from sliding onto the edge during hard use.

3. The Precision Instrument: CJRB Lanky

- Blade: The Lanky features a Wharncliffe blade. The cutting edge is perfectly straight, ending in an acute, needle-like point. This geometry transfers 100% of the user's downward force directly into the tip, making it unmatched for precision draw cuts.23

- Construction: The handle is milled from Aluminum. This provides a rigid, metallic feel that is distinct from G10 but lighter than steel. The aluminum allows for an incredibly slim profile—hence the name.

- Weight: Weighing in at approximately 1.36 oz, the Lanky is a ghost in the pocket. It is specifically engineered for users who carry other gear (phones, wallets) and cannot spare space for a bulky tool.23

4. The Hard-Use Workhorse: CJRB Tundra

- Blade: The Tundra features a massive blade, often with a stock thickness approaching 4.7mm in some heavy-duty iterations (though AR-RPM9 versions are optimized for sliciness while retaining strength). The profile is a modified drop point with a high flat grind, balancing the mass of the blade with cutting geometry.16

- Locking Security: Reliability is paramount for the Tundra. It utilizes a thick liner lock or frame lock (depending on the variant). The geometry is overbuilt to withstand shock and twisting forces that would disengage lighter locks.16

- Ergonomics: The handle is voluminous, designed to fill a large hand or a hand wearing heavy winter gloves. The red pivot collar often signifies the Tundra’s aggressive styling.25

5. The Modern Designer Collaboration: CJRB Ekko

- Blade: The Ekko features a Modified Sheepsfoot blade. It has a continuously curved edge (belly) but a dropped nose that reduces the risk of accidental punctures. It is a highly functional, non-threatening shape.

- Fidget Factor: The Ekko is the "King of Deployment." It often features a front flipper tab, a thumb hole (fuller) for "spydie-flicking," and a button lock. This allows the user to open the knife in multiple ways, making it exceptionally fun to manipulate.13

- Aesthetics: Laconico’s design language is understated. The handle lines are simple and flowing. The micarta or steel handle options allow the knife to transition from a toolbox to a dinner jacket seamlessly.

Technical Comparison: The CJRB 2026 Matrix

| Feature | Pyrite (Standard) | Gobi | Lanky | Tundra | Ekko |

|---|---|---|---|---|---|

| Primary Intent | All-Round EDC | Slicing / Tactical | Precision / Office | Hard Use / Outdoor | Fidget / Style |

| Blade Length | 3.11" (79mm) | 3.5" (89mm) | 3.58" (91mm) | ~3.8" (96mm) | 3.23" (82mm) |

| Blade Style | Drop Point | Upswept | Wharncliffe | Drop Point | Sheepsfoot |

| Lock Type | Button Lock | Liner Lock | Liner Lock | Liner/Frame Lock | Button Lock |

| Handle Material | Steel / G10 / FRN | G10 (Textured) | Aluminum | G10 / Steel | Micarta / Steel |

| Deployment | Thumb Stud / Button | Flipper Tab | Stud / Front Flipper | Flipper / Studs | Front Flipper / Hole |

| Weight | ~2.65 oz (G10) | 3.7 oz | 1.36 oz | ~7.9 oz | 3.7 oz |

Data sourced from product specifications.18

Ergonomics and Practicality: Beyond the Specs

The Weight-to-Utility Ratio

- The Lanky achieves this through material science (Aluminum), offering a full 3.58" blade at under 1.4 oz. This is an engineering marvel, providing the reach of a tactical knife with the weight of a pen.

- The Pyrite-Light uses injection-molded FRN to achieve similar weight savings in a button-lock platform. This makes it ideal for gym shorts or light summer clothing where a heavy steel knife would drag.

Pocket Clips and Carry

CJRB utilizes Deep Carry clips on almost all models. These clips are designed to allow the knife to sit completely inside the pocket, with no handle protruding.

Handle Materials and Grip Dynamics

- G10: Used on the Gobi and Tundra, G10 is impervious to moisture and temperature. CJRB’s texturing ensures that even if the handle is covered in oil or blood (for hunters), the grip remains secure.

- Micarta: Used on the Ekko and Pyrite Alt, Micarta is a fabric composite. It feels warm/organic in the hand and actually becomes grippier when wet as the fibers expand. It also develops a unique patina over time, personalizing the tool to the user.

- Steel/Titanium: Used on premium Pyrite and Ekko models, these offer rigidity and a "heirloom" quality feel, though they are heavier and can be slippery in cold conditions.

Maintenance: Ensuring Reliability for the Long Haul

Sharpening AR-RPM9

Because of the fine carbide structure, AR-RPM9 does not require diamond plates (though they work well).

- Stropping: For daily maintenance, a leather strop loaded with green compound is often enough to realign the fine edge.

- Ceramic Rods: A guided system or ceramic rod (like a Sharpmaker) is ideal. The steel abrades cleanly. Avoid coarse carbide pull-through sharpeners, as they tear the fine steel matrix rather than honing it.

- Angle: CJRB typically grinds between 17-20 degrees per side. Maintaining this angle preserves the balance between sliceyness and stability.

Bearing Maintenance

Ceramic bearings are self-polishing, but they can trap lint.

- Cleaning: Compressed air is usually sufficient to clear pocket lint from the pivot.

- Lubrication: Do not use heavy grease. A light, nano-weight oil (like KPL) is best. Because the ceramic balls are smooth, they need very little lubrication. One drop on the detent path and one in the pivot is sufficient for months of action.

- Corrosion: While the bearings won't rust, the steel liners they run on can. If the knife gets soaked, it is best to blow it out with compressed air and apply a drop of oil to protect the liners.

Conclusion: The Verdict on Value

The concept of the "Budget EDC" knife has fundamentally shifted. In 2026, a $50 bill no longer buys a compromise; it buys a high-performance tool that rivals the giants of the industry.

CJRB has driven this shift through the strategic deployment of technology. AR-RPM9 proves that you don't need to spend $200 for a powder-metallurgy-style microstructure. Ceramic Ball Bearings prove that smooth action isn't a luxury feature.

- For the user who wants one knife to do it all: The Pyrite.

- For the user who needs cutting power and reach: The Gobi.

- For the professional who needs precision and discretion: The Lanky.

- For the adventurer who demands durability: The Tundra.

- For the enthusiast who values design and interaction: The Ekko.

These knives are not just reliable "for the price." They are reliable, period. They represent a manufacturing philosophy that respects the user's need for a tool that works, cuts, and lasts, without requiring a second mortgage.

References

- CJRB AR-RPM9 Steel Collection | Free Shipping, accessed January 30, 2026, https://cjrb.net/collections/ar-rpm9

- Stop Overthinking Your First EDC Knife: The Beginner's Guide to CJRB & Artisan Cutlery, accessed January 30, 2026, https://artisancutlery.net/blogs/knife-knowledge/stop-overthinking-your-first-edc-knife-the-beginner-s-guide-to-cjrb-amp-artisan-cutlery

- D2 vs. AR-RPM9: Which Budget Steel Actually Lasts Longer? - CJRB Cutlery, accessed January 30, 2026, https://cjrb.net/blogs/knife-knowledge/d2-vs-ar-rpm9-steel-comparison

- Spray Forming: An Overview - Powder Metallurgy Manufacturer, accessed January 30, 2026, https://powdermetallurgy.com/spray-forming/

- What Is Spray Forming? | OneMonroe, accessed January 30, 2026, https://monroeengineering.com/blog/what-is-spray-forming/

- Superior Rust Resistance? 14c28n, 9CR18MoV, AR-RPM9, 154CM, AUS-10? - Reddit, accessed January 30, 2026, https://www.reddit.com/r/BudgetBlades/comments/1eaif14/superior_rust_resistance_14c28n_9cr18mov_arrpm9/

- Knife Steel Guide: AR-RPM9, AR-SF II, D2, Nitro V, CPM S30V, and More Compared, accessed January 30, 2026, https://cjrb.net/blogs/knife-knowledge/knife-steel-guide-ar-rpm9-a-sfii-cpm-154-d2-nitro-v-s30v

- Trust and Steel Designations - Everyday Commentary, accessed January 30, 2026, https://www.everydaycommentary.com/www.everydaycommentary.com/2024/5/19/trust-and-steel-designations

- New ARTISAN/CJRB spray form steel. : r/chineseknives - Reddit, accessed January 30, 2026, https://www.reddit.com/r/chineseknives/comments/1gnjm4z/new_artisancjrb_spray_form_steel/

- AR-RPM9 Knife Steel is False Advertising, accessed January 30, 2026, https://knifesteelnerds.com/2024/05/10/ar-rpm9-knife-steel-is-false-advertising/

- Knife Steels Rated by a Metallurgist - Toughness, Edge Retention, and Corrosion Resistance, accessed January 30, 2026, https://knifesteelnerds.com/2021/10/19/knife-steels-rated-by-a-metallurgist-toughness-edge-retention-and-corrosion-resistance/

- CJRB Pyrite button lock pocket knife review - pocket friendly in more ways than one, accessed January 30, 2026, https://the-gadgeteer.com/2023/02/12/cjrb-pyrite-button-lock-pocket-knife-review-pocket-friendly-in-more-ways-than-one/

- CJRB Ekko Review: Quite Possibly the Best Budget Pocket Knife Ever | GearJunkie, accessed January 30, 2026, https://gearjunkie.com/knives/cjrb-ekko-knife-review

- CJRB Pyrite Full Review - Better Than Its Budget! Here's why - YouTube, accessed January 30, 2026, https://www.youtube.com/watch?v=aK1QFp96uBM

- CJRB Cutlery: any experience? : r/BudgetBlades - Reddit, accessed January 30, 2026, https://www.reddit.com/r/BudgetBlades/comments/rq32j3/cjrb_cutlery_any_experience/

- CJRB Tundra Series: Overbuilt Power, Everyday Control, accessed January 30, 2026, https://cjrb.net/blogs/news/cjrb-tundra-series-guide

- EDC 101: Best Everyday Carry Knives for Every Budget - CJRB Cutlery, accessed January 30, 2026, https://cjrb.net/blogs/knife-knowledge/edc-101-best-everyday-carry-knives-guide

- CJRB Pyrite J1925 AR-RPM9 Steel Blade Steel Handle Folding Knives | Free Shipping - CJRB Cutlery, accessed January 30, 2026, https://cjrb.net/products/cjrb-pyrite-j1925-ar-rpm9-powder-steel-blade-steel-handle-folding-knives

- Inexpensive Version of a Budget Folder | CJRB Pyrite Light - YouTube, accessed January 30, 2026, https://www.youtube.com/watch?v=boFjPKPv3XU

- Review: CJRB - Pyrite-Light - Pine Survey -, accessed January 30, 2026, https://pinesurvey.com/review-cjrb-pyrite-light/

- CJRB Gobi J1906 AR-RPM9 Blade G10(Contoured & Cnc Pattern Texture) Handle Folding Knives, accessed January 30, 2026, https://cjrb.net/products/cjrb-gobi-j1906-d2-blade-g10contoured-cnc-pattern-texture-handle-folding-knives

- Lighting Up Your EDC: Meet the CJRB Gobi Glow-in-the-Dark Folder, accessed January 30, 2026, https://cjrb.net/blogs/news/cjrb-gobi-glow-in-the-dark-review

- The Ultimate Guide to Lightweight EDC: Why the CJRB Lanky Redefines the Slim Knife, accessed January 30, 2026, https://cjrb.net/blogs/news/ultimate-guide-lightweight-edc-cjrb-lanky

- CJRB Tundra | The Ultimate Overbuilt Powerhouse | Free Shipping, accessed January 30, 2026, https://cjrb.net/collections/cjrb-tundra

- CJRB Tundra Folding Knife - Overview & Review - YouTube, accessed January 30, 2026, https://www.youtube.com/watch?v=BbiQS0v0wJ4

- EDC Knives | Free Shipping, accessed January 30, 2026, https://cjrb.net/collections/edc-knives

- CJRB Lanky Collection | Jake Diaz Design | Slim Aluminum EDC Knives | Free Shipping, accessed January 30, 2026, https://cjrb.net/collections/the-lanky-family

- CJRB Tundra J1966 D2 Steel Blade Green G10 Handle Folding Knives | Free Shipping, accessed January 30, 2026, https://cjrb.net/products/cjrb-tundra-j1966-ar-rpm9-steel-blade-g10-handle-folding-knives

- CJRB Cutlery Ekko Button Lock Knife Black Carbon Fiber (3.3" SW) - Blade HQ, accessed January 30, 2026, https://www.bladehq.com/item--CRJB-Cutlery-Ekko-Button-Lock-Knife--181642

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.