1. Introduction: The Engineer’s Dilemma in Everyday Carry

Consider a scenario familiar to many field engineers and technicians: It is late on a Thursday evening in a humid coastal warehouse. You are tasked with dismantling a crate secured with heavy-duty, fibrous polymer strapping. You reach for your everyday carry (EDC) knife—a budget folder purchased a few years ago, featuring a D2 tool steel blade. As you apply lateral pressure to torque through the strap, there is a distinct snap. The tip of the blade, compromised by a network of coarse, brittle carbides and microscopic stress risers, has sheared off. To make matters worse, upon closer inspection under the warehouse lights, you notice the distinct orange pitting of corrosion along the pivot, a consequence of the saline humidity and D2’s semi-stainless nature.

This failure mode is not merely bad luck; it is a predictable outcome of materials science. For decades, the "budget" knife category was defined by metallurgical compromise. You could have hardness (D2), or you could have toughness and corrosion resistance (8Cr13MoV, 420HC), but rarely both, and certainly not with the refined microstructure reserved for premium powder metallurgy steels like CPM-S35VN or M390.

However, the landscape of 2026 has shifted fundamentally. We are witnessing a democratization of high-performance metallurgy, driven largely by the maturation of the Spray-Form Process in steel manufacturing. This technology has allowed manufacturers like CJRB Cutlery to break the traditional "Iron Triangle" of knife steel—Hardness, Toughness, and Cost.

This report serves as a comprehensive engineering analysis of the best budget folding knives available in 2026. We will move beyond marketing hyperbole to explore the granular mechanics of these tools. We will dissect the proprietary AR-RPM9 and AR-SFII steels1, analyze the tribology of pivot systems, and evaluate the mechanical integrity of locking mechanisms like the button lock and crossbar lock. For the engineer, the mechanic, and the discerning user, this is your guide to understanding why your next EDC Knives might just outperform the legacy premium blades of the last decade.

2. Fundamentals of Knife Steel Metallurgy

To appreciate the innovation behind modern budget knives, we must first establish a baseline understanding of steel metallurgy. A knife blade is not a homogeneous block of material; it is a complex crystalline matrix where the interplay of elements determines performance.

2.1 The Iron-Carbon Lattice and Phases of Steel

At its core, steel is an alloy of iron and carbon. The arrangement of these atoms dictates the steel's phase.

- Austenite (Gamma Iron): A face-centered cubic structure present at high temperatures. It dissolves carbon well.

- Martensite: The goal of heat treatment. By rapidly quenching austenite, we trap carbon atoms in the crystal lattice, distorting it into a body-centered tetragonal structure. This internal stress is what gives hardened steel its strength and hardness.2

- Ferrite (Alpha Iron): The softer, body-centered cubic form of iron.

In budget knives of the past, inconsistencies in the transition from austenite to martensite—often due to poor heat control or uneven chemical composition—led to "soft spots" or brittle zones. Modern manufacturing now allows for precise control over these phase transformations.

2.2 Alloying Elements: The Ingredients of Performance

While carbon provides the hardness, alloying elements define the personality of the steel.

- Chromium (Cr): The defining element of stainless steel. It forms a passive oxide layer (passivation) on the surface that blocks oxygen from reacting with the iron. To be truly "stainless," a steel generally needs at least 10.5-12% free chromium.2

- Molybdenum (Mo): Critical for pitting resistance. It reinforces the passive film formed by chromium, especially in chloride-rich environments (like sweat or sea air). It also promotes hardenability.1

- Vanadium (V): The "muscle" of edge retention. Vanadium forms extremely hard carbides (VC) that resist abrasive wear. It also acts as a grain refiner, pinning grain boundaries to prevent them from growing too large during heat treatment.1

- Nickel (Ni): A key toughening agent. Unlike carbide formers, nickel strengthens the ferrite matrix itself, improving impact resistance and ductility at low temperatures.1

2.3 Carbide Morphology: The Microscopic Teeth

Carbides are hard particles formed when carbon bonds with alloying elements. They are the "rocks" in the "concrete" of the steel matrix.

- Chromium Carbides (M7C3, M23C6): Harder than steel but softer than vanadium carbides. They provide wear resistance but, if they grow too large (as in D2), they become brittle fracture points.5

- Vanadium Carbides (MC): Extremely hard (up to 2800 Vickers). Small, evenly distributed vanadium carbides are the gold standard for high-performance edges.4

The size and distribution of these carbides are the primary differentiators between "budget" and "premium" performance. Large, blocky carbides (common in ingot casting) act like stress risers—cracks start here. Fine, diffuse carbides (common in spray-forming) act like aggregate reinforcement, stopping cracks from propagating.3

3. Manufacturing Processes: The Engineering of Steel

The distinction between a $30 gas station knife and a CJRB Pyrite lies largely in how the steel was born.

3.1 Ingot Casting: The Legacy Bottleneck

Traditionally, budget steels like 440C or D2 are produced via ingot casting. Molten steel is poured into a large mold and allowed to cool.

- The Segregation Problem: As the large ingot cools slowly, elements with higher melting points solidify first. Carbon and alloying elements are rejected into the remaining liquid, creating pools of alloy-rich material.

- Result: This leads to "segregation" or "banding." You get clumps of massive chromium carbides surrounded by alloy-depleted steel.

- Impact on Knives: The clumps are brittle (low toughness). The depleted areas corrode easily (rust spots). This is why D2, despite having high carbon, is prone to chipping and rusting.7

3.2 Powder Metallurgy (PM): The Premium Solution

To solve segregation, the industry developed Particle Metallurgy (e.g., CPM steels).

- Process: Molten metal is blasted through a nozzle by high-pressure gas, atomizing it into microscopic droplets that freeze instantly. These powder particles are then sintered under heat and pressure (Hot Isostatic Pressing - HIP).

- Result: Zero segregation. Every particle is a perfect micro-ingot. Carbides are micron-sized and evenly distributed.

- Drawback: Cost. The process is energy-intensive and expensive, keeping these steels out of the budget range.9

3.3 The Spray-Form Process: The Budget Revolution

This is the technology that powers AR-RPM9 and AR-SFII, enabling CJRB pocket knives to compete with mid-tier options.

- Mechanism: Similar to PM, the steel is atomized by inert gas (Nitrogen). However, instead of freezing into powder, the semi-solid droplets are sprayed directly onto a rotating substrate to build up a billet.11

- Thermal Dynamics: The droplets impact the substrate while still semi-liquid/semi-solid. This allows them to weld together instantly without the need for the expensive HIP sintering step of PM.11

- Microstructural Advantage: The rapid solidification (though slightly slower than PM) prevents carbide clumping. The result is a fine, uniform grain structure that is drastically superior to ingot casting but significantly cheaper to produce than PM.13

Table 1: Manufacturing Process Comparison

| Feature | Ingot Casting (e.g., Standard D2) | Spray-Forming (e.g., AR-RPM9) | Powder Metallurgy (e.g., CPM-S35VN) |

| Cooling Rate | Slow | Rapid | Very Rapid |

| Carbide Size | Large, Irregular (10-50+ microns) | Fine, Uniform (2-5 microns) | Very Fine (<2 microns) |

| Segregation | High (Banding issues) | Very Low | Zero |

| Toughness | Low (Brittle) | High | Very High |

| Cost | Low | Moderate (The "Sweet Spot") | High |

1

4. Deep Dive: AR-RPM9 Steel Analysis

AR-RPM9 is the proprietary steel that put CJRB on the map for serious enthusiasts. It was engineered specifically to solve the "D2 Problem"—the issue where budget knives had good edge retention but poor toughness and corrosion resistance.

4.1 Chemical Composition & Engineering Function

The composition of AR-RPM9 is a masterclass in balancing cost and performance for EDC (Everyday Carry).

| Element | Content | Function in AR-RPM9 |

|---|---|---|

| Carbon | 0.90% | Sufficient for high hardness (HRC 59-61) without excessive brittleness.1 |

| Chromium | 18.00% | Extremely high. Guarantees a robust passive film for exceptional corrosion resistance.1 |

| Molybdenum | 1.00% | Enhances hardenability and pitting resistance.1 |

| Vanadium | 0.10% | Grain refinement. Kept low to maintain ease of sharpening.1 |

| Cobalt | 0.30% | Strengthens the matrix at higher temperatures.1 |

| Nickel | <0.40% | Improves impact toughness.1 |

4.2 Microstructure and Performance Mechanics

Because AR-RPM9 utilizes the Spray-Form Process, it avoids the large chromium carbide streaks found in 9Cr18MoV or D2.

- Toughness: The fine grain structure means that when the edge impacts a staple or wire, the energy is dissipated through a uniform matrix rather than concentrating at a large carbide interface. This prevents catastrophic chipping.1

- Corrosion Resistance: With 18% Chromium distributed evenly (not tied up in massive carbide clumps), the steel forms a continuous, self-healing oxide layer. It is a "true stainless," unlike the semi-stainless D2.16

- Sharpenability: This is a critical user advantage. Large carbides in D2 are hard to abrade; they tend to tear out of the matrix during sharpening, leaving a jagged edge. AR-RPM9's fine carbides stay anchored, allowing the user to hone the edge to a razor-like polish using standard ceramic or aluminum oxide stones.16

5. Deep Dive: AR-SFII Steel Analysis

In 2025, CJRB introduced AR-SFII steel as the "Next-Generation Engine." If RPM9 is the reliable sedan, SFII is the turbocharged sport model.

5.1 Evolution of the Alloy

AR-SFII was designed to address the one area where RPM9 was merely "good"—edge retention. By aggressively modifying the chemistry, CJRB pushed the steel into a higher performance tier.

| Element | AR-RPM9 | AR-SFII | Delta | Engineering Impact |

|---|---|---|---|---|

| Carbon | 0.90% | 1.11% | +0.21% | Higher potential hardness and carbide volume.1 |

| Molybdenum | 1.00% | 3.75% | +2.75% | Massive increase. Dramatically boosts wear resistance and corrosion resistance.1 |

| Vanadium | 0.10% | 1.11% | +1.01% | Introduces hard Vanadium Carbides (VC) for aggressive cutting "bite".1 |

| Chromium | 18.00% | 14.70% | -3.30% | Reduced slightly to balance the matrix, but still well above the stainless threshold.1 |

5.2 Performance Mechanics of AR-SFII

- The Molybdenum Factor: The jump to 3.75% Molybdenum is significant. Mo works synergistically with Chromium to prevent pitting corrosion. More importantly, it forms hard Mo-carbides that resist abrasive wear (like cutting cardboard) much better than simple iron carbides.1

- Vanadium Carbide Injection: The increase to 1.11% Vanadium introduces VC particles. These are harder than the abrasive materials typically cut (silica in cardboard, dirt). This allows AR-SFII to hold a working edge significantly longer than RPM9.1

- Trade-offs: While harder and more wear-resistant, AR-SFII is slightly more difficult to sharpen than RPM9 due to the harder vanadium carbides, though still easier than S90V. The spray-form process ensures it retains toughness, avoiding the brittleness of high-carbon ingot steels.20

6. Comparative Engineering: The Battle of the Steels

To properly situate the CJRB pocket knives of 2026, we must benchmark them against the old guard.

6.1 AR-RPM9 vs. D2 (Ingot)

- The D2 Legacy: D2 has high wear resistance due to massive Chromium Carbides. However, these carbides are its Achilles heel. They make the steel brittle (low toughness) and "toothy" but hard to polish.

- The RPM9 Advantage: RPM9 matches D2's working edge retention but exceeds it vastly in toughness and corrosion resistance. In a "salt spray" simulation or a "spine whack" impact test, RPM9 survives where D2 corrodes or chips.16

- Verdict: For EDC, RPM9 is superior. D2 is obsolete for general pocket knives in 2026, relegated to specific abrasive cutting tasks where brittleness is acceptable.

6.2 AR-SFII vs. CPM-S30V

- The S30V Standard: S30V (Powder Metallurgy) uses 1.45% Carbon and 4% Vanadium. It is a wear resistance monster. However, it is infamous for being difficult to sharpen and prone to "micro-chipping" if the heat treat isn't perfect.23

- The SFII Challenger: AR-SFII approaches S30V levels of performance but utilizes the Spray-Form process to keep costs down. With 3.75% Mo and 1.11% V, it offers a "sticky" sharp edge that is less prone to micro-chipping than S30V due to the spray-form grain structure.1

- Verdict: S30V still holds a slight edge in pure abrasion resistance, but AR-SFII offers 90% of the performance at 50% of the cost, with better toughness.19

Table 2: 2026 Steel Performance Matrix

| Steel | Process | Edge Retention | Toughness | Corrosion Resistance | Sharpenability |

|---|---|---|---|---|---|

| AR-RPM9 | Spray-Form | 6.5/10 | 8/10 | 9/10 | 9/10 16 |

| AR-SFII | Spray-Form | 8/10 | 7.5/10 | 8.5/10 | 7/10 1 |

| D2 (Cast) | Ingot | 7.5/10 | 4/10 | 4/10 | 4/10 21 |

| CPM-S30V | PM | 9/10 | 5/10 | 8/10 | 5/10 24 |

7. Mechanical Systems Engineering

A blade is useless without a reliable mechanism to deploy and lock it. 2026 has seen the refinement of locking mechanisms in the budget sector.

7.1 The Physics of the Button Lock (Plunge Lock)

The CJRB Pyrite has become the dominant mechanism for fidget-friendly EDC.

- Mechanics: A spring-loaded plunger (the button) intersects the blade tang. When open, the plunger slides into a notch in the tang, blocking rotation. Pressing the button compresses the spring, moving the plunger out of the notch. 26

-

Engineering Advantages:

- Safety: Fingers never cross the blade path during closing.

- Friction: Unlike liner locks which rely on friction against the tang face, button locks rely on mechanical interference. This allows for a free-swinging blade ("drop shut" action). 28

- Failure Modes: If the tolerance between the plunger and notch is loose, "lock rock" (vertical play) can occur. CJRB has mitigated this with precision machining in models like the Pyrite. 30

7.2 The Liner Lock: Elastic Deformation

- Mechanics: A leaf spring cut into the handle liner is bent inward. When the blade opens, the liner springs behind the tang, wedging it open. 31

- Stress Analysis: The lock relies on the elastic modulus of the liner material (usually stainless steel). It fails if the liner buckles under load or slips off the tang face due to poor geometry (slip angle). 32

- Utility: Still preferred for hard-use budget knives like the Gobi due to simplicity and fewer moving parts than a button lock. 33

7.3 The Crossbar Lock

Found on the CJRB Prado, this mechanism uses a horizontal steel bar pulled by two omega springs into a notch in the tang. 34

- Strength: The lock bar engages the tang on both sides, creating a dual shear point. It is mechanically stronger than a liner lock or button lock, capable of supporting immense negative loads. 36

- Ambidexterity: Fully accessible from both sides, making it ideal for left-handed users.

7.4 Pivot Tribology: Bearings vs. Washers

Most 2026 budget knives, including the Pyrite and Gobi, use Ceramic Ball Bearings in a caged assembly. 28

- Tribology: Ceramic (Silicon Nitride) is harder and smoother than steel. It reduces the coefficient of friction significantly compared to phosphor bronze washers.

- Result: The "action" is snappy and smooth. However, bearings are susceptible to grit intrusion. For pure outdoor survival, washers are preferred, but for EDC, bearings rule. 38

8. Product Specific Engineering Reviews

Based on the metallurgical and mechanical analysis, here are the top engineered choices for 2026.

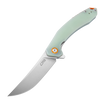

8.1 The CJRB Pyrite Family: The Modular Platform

The Pyrite Family represents a modular engineering platform rather than a single knife. It is the definitive EDC knives.

-

Standard Pyrite:

- Steel: AR-RPM9 (Spray-Form).

- Lock: Button Lock.

- Analysis: The neutral handle geometry accommodates various grip styles (hammer, saber, pinch). The steel liners are skeletonized (holes drilled out) to reduce mass without compromising structural rigidity (Moment of Inertia).28

-

Pyrite-Alt (Wharncliffe):

- Geometry: A straight edge transfers force directly into the material without the tip slipping off. This is mechanically superior for draw cuts (opening boxes).39

-

Pyrite-Light:

- Materials: Uses AR-RPM9/AR-SFII steel paired with FRN (Fiber-Glass Reinforced Nylon) handles.

- Engineering: FRN is an injection-molded polymer matrix composite. It offers high tensile strength-to-weight ratio. By using FRN, CJRB reduces weight significantly while upgrading the steel to the wear-resistant SFII, creating a high-performance lightweight carry.25

8.2 The Gobi Family: Trailing Point Geometry

The Gobi Family serves a different engineering purpose: Slicing.

- Blade Mechanics: The Gobi features a trailing point blade with a significant "belly" (curvature). This increases the linear length of the cutting edge relative to the blade length.

- Shear Dynamics: When slicing (draw cutting), the curve changes the angle of attack continuously, maintaining efficient shear forces against the material (meat, rope, food).40

- Material Science: The J1906-GD model uses Glow-in-the-dark G10. This is a glass-epoxy composite doped with phosphorescent aluminates. It maintains the mechanical rigidity of G10 while adding functional visibility.42

8.3 The New Guard: Prado and Frack

- CJRB Prado: A large folder designed by Ray Laconico. It utilizes AR-SFII steel and a Crossbar Lock. The large handle uses Micarta (phenolic resin composite), which provides grip even when wet due to its fibrous surface texture. This is a "Bugout-killer," offering superior steel and lock strength at a fraction of the price.35

- CJRB Frack: A robust model often featuring CPM-S90V or AR-RPM9. It uses a "Frag Pattern" texture on the handle—a tessellated grid that maximizes static friction for grip security without being abrasive to pockets.44

9. Maintenance and Tribology: Keeping the Edge

Owning a high-performance knife requires understanding how to maintain it. The spray-form steels require specific care protocols.

9.1 Sharpening Physics

Sharpening is the process of controlled abrasion to reform the apex of the edge.

- AR-RPM9 Strategy: Because the carbides are fine and uniform, this steel does not require diamond stones. Standard aluminum oxide (India stones) or Arkansas stones work perfectly. The fine grain structure minimizes "burr tenacity," meaning the waste metal strip (burr) falls off cleanly, leaving a crisp edge.16

- AR-SFII Strategy: Due to the higher Vanadium Carbide content (1.11%), standard stones may cut slowly. A silicon carbide or diamond plate is recommended for re-profiling. However, for maintenance, a ceramic rod is sufficient.20

9.2 Optimal Edge Angles

The "Edge Angle" is the vector along which cutting force is applied.

- 20 Degrees (Per Side): The universal standard. It provides a triangle of support behind the apex that is robust enough to resist rolling (plastic deformation) during general tasks. Ideal for Pyrite and Frack.45

- 17 Degrees (Per Side): A high-performance slicing angle. AR-RPM9 is tough enough to support this acute angle for food prep or light EDC, maximizing the Gobi's slicing potential.45

9.3 Corrosion Inhibition

While AR-RPM9 is 18% Chromium, "Stainless" is not "Stain-proof."

- Crevice Corrosion: Moisture trapped in the pivot bearing cage can cause localized corrosion.

- Protocol: Apply a micro-drop of food-safe mineral oil to the pivot and blade tang monthly. This creates a hydrophobic barrier.22

10. Conclusion

In 2026, the term "budget knife" is a misnomer. Through the engineering marvel of the Spray-Form Process, companies like CJRB have bypassed the metallurgical limitations of the past. Steels like AR-RPM9 provide a toughness and corrosion resistance profile that legacy ingot steels like D2 simply cannot match mechanically. The evolution to AR-SFII brings edge retention that rivals premium powder metallurgy options.

When combined with precision-machined Button Locks and Ceramic Bearings, knives like the Pyrite and Gobi are not just "good for the money"—they are objectively high-performance engineering tools. For the user, this means less time sharpening, less fear of failure in the field, and a tool that functions as an extension of the will.

11. FAQ: Comprehensive Engineering Insights

What is the primary difference between Spray-Forming and Powder Metallurgy?

Both use gas atomization to create fine droplets. In Powder Metallurgy (PM), droplets freeze into powder, which is then sintered under high pressure (HIP). In Spray-Forming (Osprey process), semi-solid droplets impact a substrate and weld together instantly. Spray-forming achieves 90-95% of the microstructural quality of PM but at a significantly lower energy and financial cost, making it ideal for high-performance budget steels.1

Is AR-RPM9 better than D2 for a work knife?

From an engineering standpoint, yes. D2 suffers from carbide segregation (clumping), making it prone to chipping and corrosion. AR-RPM9 has a finer grain structure, making it 2-3x tougher and virtually rust-proof (18% Cr vs 12% Cr). While D2 may hold a "toothy" working edge slightly longer in abrasive cardboard, RPM9 is a far more reliable and durable material for general use.1

Can I use AR-SFII for prying?

While AR-SFII is tougher than D2, no hardened knife steel is designed for prying. The high hardness (HRC 59-61) required for edge retention means the material has limited ductility. Prying applies lateral shear forces that can exceed the yield strength of the blade, causing catastrophic failure. Use a pry bar; let the knife cut.49

Why does my button lock knife have "lock stick"?

Lock stick occurs when the friction surfaces (the steel plunger and the blade tang) gall or bind. This is often due to surface roughness or residue. It usually breaks in with use. A small amount of graphite (pencil lead) on the tang interface can lubricate the lock face without attracting grit like oil does.30

How does the glow-in-the-dark handle on the Gobi work?

The G10 composite is impregnated with a phosphorescent pigment (likely Strontium Aluminate). These crystals absorb UV photons and re-emit them as visible light over time. Unlike old zinc-sulfide glow materials, modern aluminates are chemically stable and can glow for hours after charging.42

What sharpening grit should I finish AR-RPM9 with?

Because AR-RPM9 has a fine grain structure, it benefits from a polished edge. Finishing with a 1000-3000 grit ceramic stone or a leather strop loaded with compound will produce a "hair-popping" edge. Coarse grits (300-600) are only necessary for repairing damage or re-profiling.47

Is the Crossbar Lock on the Prado stronger than the Button Lock on the Pyrite?

Generally, yes. The Crossbar Lock engages the tang with a solid steel bar supported on both sides of the liners, distributing the load more evenly. The Button Lock relies on a single plunger. While both are more than adequate for EDC, the Crossbar Lock has a higher theoretical failure load.34

References

- Works Cited AR-RPM9 & AR-SFII Steel Types And Metallurgy 101 - Element Knife Company

- Carbide Types in Knife Steels

- Wear and Corrosion Resistance of Chromium–Vanadium Carbide Coatings

- How Hard Is Your Chromium Carbide Overlay (CCO) Steel?

- Is the secret to high-quality knife steel in the microstructure?

- From steel to semi-finished products | tec-science

- Conventional, Spray Form and Powder Metallurgy - Alloys in Tool Steel

- Powder metallurgy vs. investment casting – what are the differences?

- Powder Metallurgy VS. Casting

- Spray Forming: An Overview

- Spray forming - Wikipedia

- Spray Forming: Alloys, Products, and Markets

- THE PERFORMANCE OF SPRAY-FORMED TOOL STEELS

- Anyone have experience with AR-RPM9 steel? : r/BudgetBlades

- D2 vs. AR-RPM9: Which Budget Steel Actually Lasts Longer?

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.