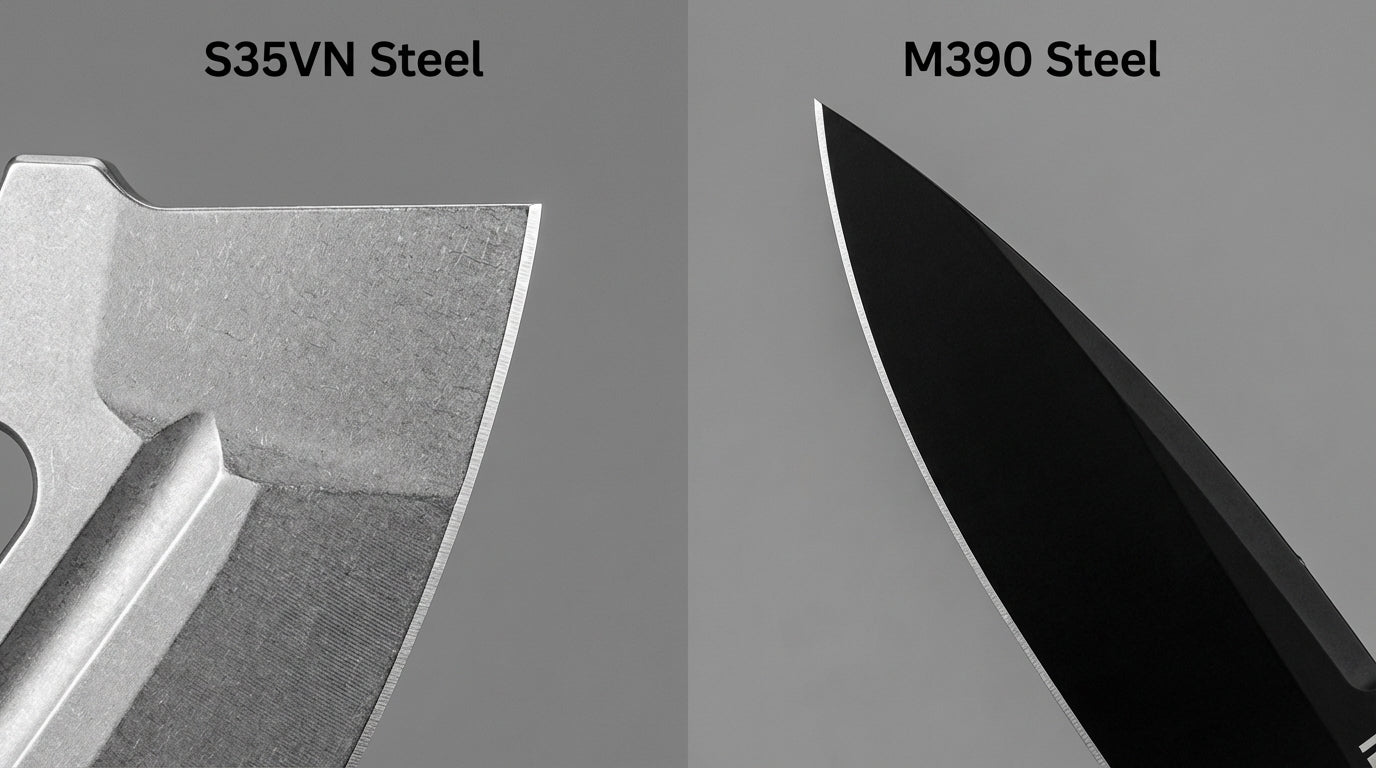

When investing in a high-quality Everyday Carry (EDC) knife, the conversation inevitably turns to the heart of the tool: the steel. In the modern era of cutlery, we are blessed with "super steels"—alloys engineered with particle metallurgy to achieve performance levels that were impossible just a few decades ago. Among these titans of the industry, two names frequently rise to the top of the debate: CPM S35VN and Böhler M390.

Choosing between s35vn vs m390 is not simply a matter of picking the "better" steel; it is about selecting the right set of attributes for your specific lifestyle and usage patterns. Both steels represent the pinnacle of modern metallurgy, yet they achieve their reputation through different chemical pathways and offer distinct advantages. For the uninitiated, the technical jargon of carbides, Rockwell hardness, and grain structure can be overwhelming. However, understanding these nuances is critical to ensuring your investment lasts a lifetime.

In this comprehensive guide, we will dissect the molecular composition, real-world performance, and maintenance requirements of both steels. We will move beyond the marketing hype to provide a scientific and practical analysis. Whether you are a collector looking for the ultimate safe queen or a hard-use outdoorsman needing a reliable companion, this breakdown will illuminate the path to your perfect blade.

Understanding Knife Steel Metallurgy: The Basics

Before pitting s35vn vs m390 against one another, it is essential to establish a baseline understanding of what makes a steel "super." At its core, steel is an alloy of iron and carbon. However, the performance characteristics—how long it stays sharp, how easily it resists rust, and how much abuse it can take—are determined by the addition of other elements and the manufacturing process used to combine them.

The Role of Carbides

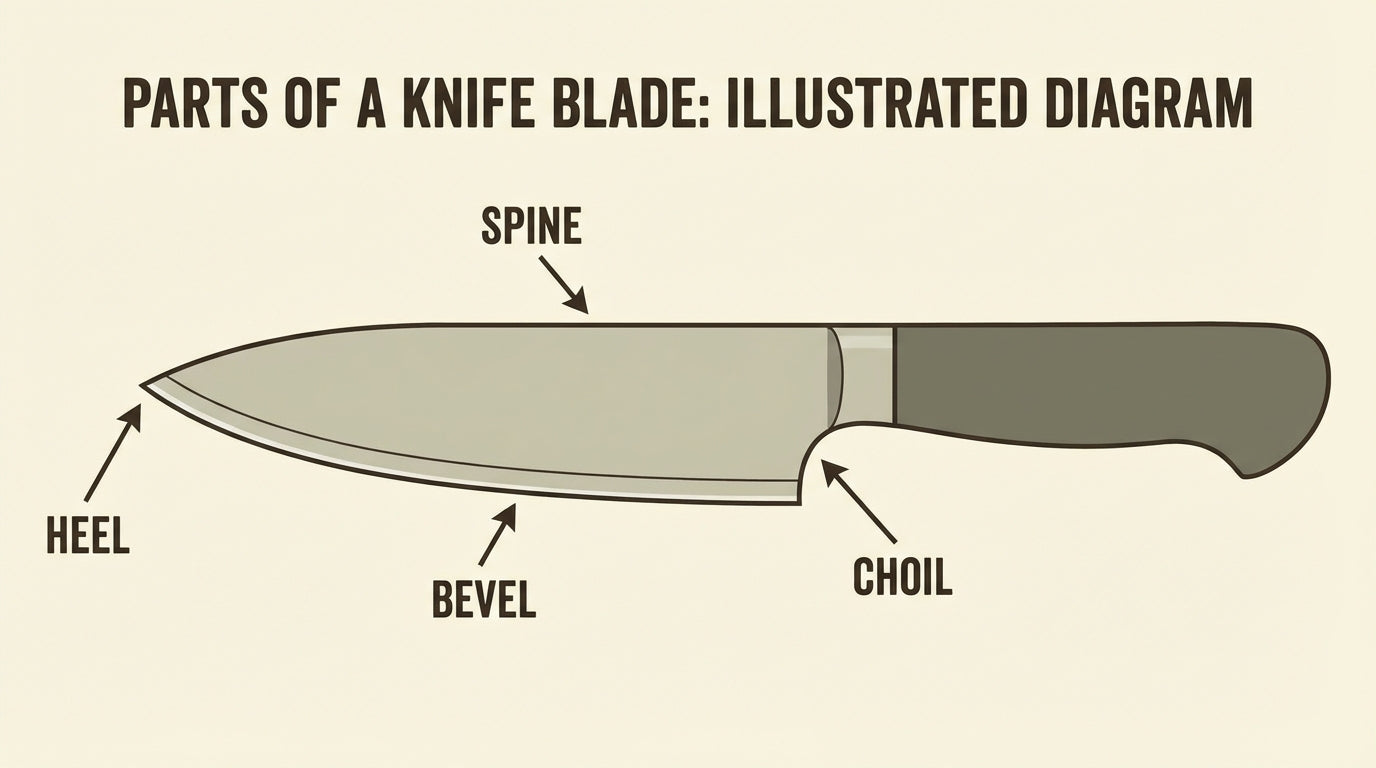

In high-performance knife steels, carbon bonds with other elements like Vanadium, Chromium, and Molybdenum to form hard particles known as carbides. Think of the steel matrix as concrete and the carbides as the rocks or aggregate within that concrete. The harder the carbides, the better the edge retention.

- Vanadium Carbides: These are among the hardest carbides formed in steel. They contribute significantly to wear resistance, allowing the knife to cut through abrasive materials like cardboard or rope for extended periods.

- Chromium Carbides: While also hard, their primary role is often associated with corrosion resistance. High chromium content creates a passive film on the surface of the steel that prevents oxidation (rust).

The balance and size of these carbides are what differentiate a standard kitchen knife from a high-end tactical folder. If the carbides are too large, the steel becomes brittle and prone to chipping. If they are too small or sparse, the edge won't hold.

Grain Structure and Powder Metallurgy

Both S35VN and M390 are products of Powder Metallurgy (PM). In traditional steel making, molten alloy is poured into ingots. As it cools, elements can segregate, creating uneven structures and large, clunky carbides. Powder Metallurgy changes the game. The molten steel is atomized into a fine mist that solidifies instantly into microscopic powder. This powder is then fused under immense heat and pressure.

The result is a steel with an incredibly fine, uniform grain structure. This homogeneity means the steel can support a finer edge, is tougher (less likely to snap), and is easier to grind than a conventionally cast steel of the exact same chemical composition. This technology is the foundation upon which the reputation of both S35VN and M390 is built.

The Holy Trinity: Toughness, Edge Retention, Corrosion Resistance

Every knife steel design is a balancing act between three competing properties:

- Edge Retention: The ability to resist wear and keep a sharp edge during use.

- Toughness: The ability to absorb energy without fracturing or chipping (impact resistance).

- Corrosion Resistance: The ability to resist rust and staining from moisture, salt, and acids.

Generally, increasing edge retention (adding more hard carbides) decreases toughness. Increasing corrosion resistance (adding more chromium) can sometimes compromise edge stability if not heat-treated correctly. The battle of s35vn vs m390 is essentially a debate over which compromise is more acceptable for the user.

Deep Dive into CPM S35VN

CPM S35VN was developed by Crucible Industries in collaboration with legendary knife maker Chris Reeve. It was designed specifically to be an improvement over its predecessor, S30V, which was already an industry standard but was criticized for being somewhat difficult to sharpen and prone to micro-chipping.

Chemical Composition and Niobium Addition

The "VN" in S35VN stands for Vanadium and Niobium. The genius of S35VN lies in the addition of 0.5% Niobium. Niobium carbides are very hard, but they are also much smaller than vanadium carbides. By substituting some vanadium for niobium, Crucible created a steel that maintains the incredible wear resistance of S30V but with a significantly finer grain structure.

| Element | Composition (%) | Function |

|---|---|---|

| Carbon | 1.40% | Hardness & Wear Resistance |

| Chromium | 14.00% | Corrosion Resistance |

| Vanadium | 3.00% | Wear Resistance |

| Niobium | 0.50% | Grain Refinement & Toughness |

| Molybdenum | 2.00% | Hardenability & Strength |

Performance Profile: The "Goldilocks" Steel

S35VN is often referred to as the ultimate "Goldilocks" steel. It isn't the absolute best at any single thing, but it is excellent at everything. It is tougher than M390, easier to sharpen, and holds an edge far longer than budget steels like 440C or D2. Its toughness makes it less likely to chip if you accidentally hit a staple while cutting a box or if you need to perform light prying tasks (though prying with a knife is never recommended!).

For users who want a high-end steel that doesn't require diamond stones and hours of labor to resharpen, S35VN is the superior choice. It represents a sweet spot in metallurgy where performance meets maintainability.

Real-World Applications and CJRB S35VN Highlights

Because of its balanced nature, S35VN is perfect for general-purpose EDC, hunting knives, and tactical blades where reliability is paramount. It can handle the shock of impact better than harder steels, making it a favorite for survival scenarios.

At CJRB, we have embraced this legendary steel to offer users a premium cutting experience without the fragility often associated with high-hardness alloys.

Discover the CJRB S35VN Collection

Discover excellence with CJRB's S35VN collection, where the stellar balance of sharpness, toughness, and wear resistance is brought to life in each blade. Our knives, crafted with the legendary CPM S35VN steel, provide an optimal cutting experience, ensuring your blade retains its edge longer while providing impeccable performance. Navigate through a world where advanced steel metallurgy meets refined knife-making and find a blade that stands the test of time.

Deep Dive into Bohler M390

If S35VN is the balanced all-rounder, Böhler M390 is the high-performance specialist. Manufactured by Böhler-Uddeholm, M390 is often cited as one of the best all-around knife steels on the market, but its bias is heavily leaned toward edge retention and corrosion resistance. It is a "super steel" in the truest sense of the term.

Chemical Composition and Chromium/Vanadium Content

M390 is technically a martensitic chromium super-clean stainless steel. The chemical composition is staggering, particularly in its Chromium and Vanadium content.

| Element | Composition (%) | Function |

|---|---|---|

| Carbon | 1.90% | Extreme Hardness |

| Chromium | 20.00% | Extreme Corrosion Resistance |

| Vanadium | 4.00% | Extreme Wear Resistance |

| Molybdenum | 1.00% | Strength |

| Tungsten | 0.60% | Wear Resistance |

The massive 20% Chromium content makes M390 almost impervious to rust in normal conditions. The 4% Vanadium and 1.9% Carbon allow it to reach high hardness (HRC 60-62) with a massive volume of vanadium carbides for cutting aggression.

Performance Profile: The Edge Retention King

When discussing s35vn vs m390, M390 is the clear winner in edge retention. It can slice through abrasive materials like cardboard, carpet, and sisal rope for significantly longer than S35VN before needing a touch-up. For the user who hates sharpening or needs a knife that will last through a week of intense warehouse work without faltering, M390 is the grail.

However, this comes at a cost. M390 is more difficult to machine, making the knives more expensive. It is also slightly less tough than S35VN, meaning the edge is more prone to micro-chipping if it hits a hard object like a rock or bone.

Why Enthusiasts Choose CJRB M390

M390 is the choice for the perfectionist. It offers a level of polish and performance that is hard to beat. Because of its high corrosion resistance, it is also ideal for humid environments or coastal living.

Experience the CJRB M390 Collection

Experience top-tier edge performance with the CJRB M390 Steel Collection. M390 is a premium stainless steel renowned for its exceptional edge retention, corrosion resistance, and cutting efficiency—making it one of the most trusted choices among serious EDC users. This collection brings together high-performance designs engineered for long-lasting sharpness, reliability, and everyday versatility. Whether for work, outdoors, or collection, M390 delivers uncompromising quality.

S35VN vs M390: The Head-to-Head Comparison

To truly understand the differences, we must look at the data side by side. Below is a detailed breakdown of how these two super steels compare across the most critical categories.

Edge Retention Battle

This category measures how long the blade stays sharp (CATRA testing). M390 dominates here due to its higher volume of vanadium carbides and higher attainable hardness.

| Attribute | CPM S35VN | Böhler M390 | Winner |

|---|---|---|---|

| Edge Retention |

6/10 |

9/10 |

M390 🏆 |

| Corrosion Resistance |

7/10 |

9.5/10 |

M390 🏆 |

| Toughness |

6/10 |

4/10 |

S35VN 🏆 |

| Ease of Sharpening |

6/10 |

3/10 |

S35VN 🏆 |

Toughness and Chip Resistance

Toughness measures the energy required to break the steel. While neither of these are "shock steels" (like carbon spring steels used in swords), S35VN has a clear advantage. The addition of Niobium and the lower volume of massive carbides mean the steel matrix is more cohesive.

If you drop an S35VN blade on concrete, the tip might roll (bend). If you drop an M390 blade, the tip is more likely to snap or chip. For hard outdoor use—whittling, processing game, cutting zip ties—S35VN provides a safety margin that M390 lacks.

Corrosion Resistance and Maintenance

M390 is a true champion here. You can carry M390 in a sweaty pocket during a humid summer day, or take it on a saltwater fishing trip (with a rinse afterward), and it will likely remain spotless. S35VN is stainless, but with 14% chromium compared to M390's 20%, it is more susceptible to spotting if neglected. M390 allows for a "lower maintenance" lifestyle regarding rust prevention.

Sharpening and Grindability

One of the most overlooked aspects of owning a knife is the maintenance. Eventually, even M390 will get dull. This is where the user experience differs dramatically between the two.

Ease of Sharpening S35VN

S35VN is widely praised for being user-friendly. While it is harder than cheap steels, it responds very well to standard sharpening systems. The Niobium carbides, while hard, are small and do not clog stones as aggressively as massive vanadium clusters. You can achieve a hair-popping edge on S35VN using standard aluminum oxide stones, though ceramic or diamond is preferred for speed.

The Challenge of M390

Sharpening M390 can be a humbling experience for beginners. The wear resistance that keeps the edge sharp also resists the abrasive action of sharpening stones. It takes significantly longer to remove material and form a burr.

If you let M390 get completely dull, bringing it back to life is a chore. It requires patience and consistent angle control. However, once that edge is achieved, it takes a very keen polish, often looking like a mirror due to the high chromium content.

Recommended Abrasives and Techniques

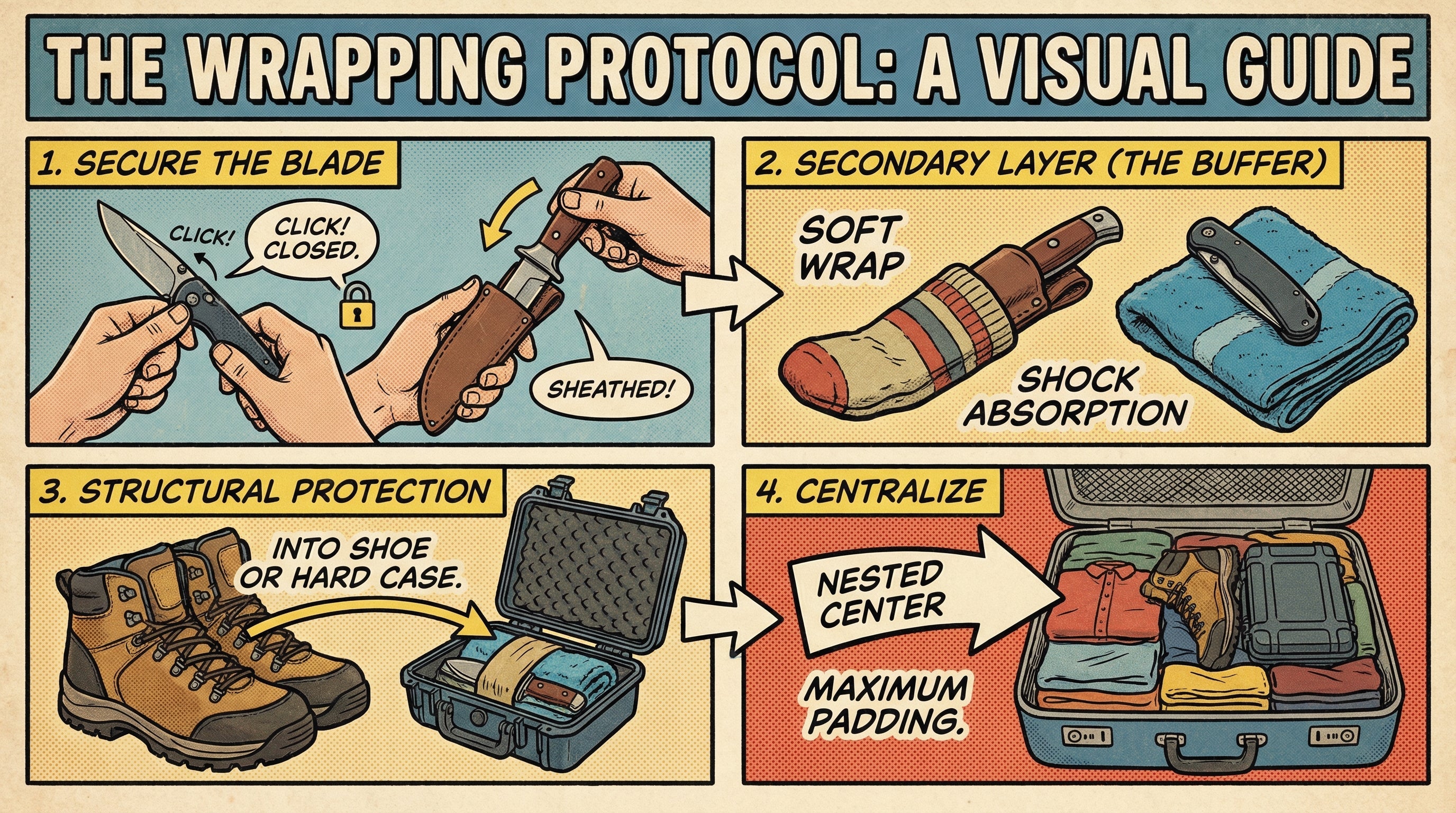

Regardless of which steel you choose, upgrading your sharpening gear is recommended.

- 1 Diamond Plates: Essential for M390. Diamond cuts through vanadium carbides efficiently.

- 2 Ceramic Rods: Excellent for maintaining S35VN.

- 3 Strops: Use a leather strop with diamond compound (1 micron or lower) for both steels. Stropping M390 frequently can delay the need for a full sharpening session by months.

Cost and Value Proposition

Price is often the deciding factor. Why does M390 usually command a higher price tag?

Manufacturing Costs and Difficulty

The raw material cost of M390 is higher than S35VN. More importantly, the processing cost is higher. M390 eats through the belts and grinding wheels of the knife maker. It takes longer to grind the bevels, longer to satin finish, and longer to sharpen at the factory. These machine hours and consumable costs are passed down to the consumer.

Price Point Analysis for the Consumer

Generally, you can expect to pay a premium of $20 to $50 (or more) for a knife in M390 compared to an identical model in S35VN. S35VN sits in the "premium but accessible" price bracket, while M390 sits in the "ultra-premium" bracket.

Which Offers Better ROI?

If you value time (less sharpening) and aesthetics (corrosion resistance), M390 offers a great Return on Investment. If you value durability and ease of use, S35VN is the better value play. S35VN gives you 85% of the performance of the most expensive steels at a significantly more attractive price point.

Beyond S35VN and M390: Other Steels to Consider

The world of metallurgy doesn't end with these two. To make an informed decision, it helps to know the family tree and the competition.

The Predecessor: S30V

CPM S30V was the industry standard for a long time. It has slightly better edge retention than S35VN but is harder to sharpen and more prone to chipping. S35VN has largely replaced it in new designs because the trade-off for toughness was deemed worth the slight reduction in edge holding.

The Successor: S45VN

Crucible recently released CPM S45VN. It attempts to bridge the gap, offering more corrosion resistance and edge retention than S35VN without sacrificing too much toughness. It is slowly entering the market, but S35VN remains more widely available and affordable.

The Competitor: 20CV and 204P

If you see CPM-20CV or CTS-204P listed on a knife, know that these are essentially chemically identical to M390. 20CV is made by Crucible (USA), and 204P is made by Carpenter (USA), while M390 is made by Bohler (Austria). The performance differences between these three are negligible and often come down to the quality of the heat treat rather than the steel itself.

Choosing the Right Steel for Your Lifestyle

So, who wins the s35vn vs m390 debate? There is no single winner, only the right tool for the job.

For the Hard-Use Outdoorsman

Choose S35VN. When you are in the woods, you need a knife that won't snap if you twist it slightly while processing wood or game. You also need a knife that you can field sharpen with a simple pocket stone. The toughness and sharpenability of S35VN make it the superior survival and camping choice.

For the Urban EDC User

Choose M390. In an urban environment, you are cutting cardboard boxes, plastic packaging, and perhaps an apple at lunch. The primary enemy is abrasive wear (cardboard is surprisingly abrasive!). M390's edge retention means you can go months without sharpening. The corrosion resistance is a bonus for pocket carry.

For the Collector

Choose M390. Collectors value the "best of the best." M390 holds its value better on the secondary market and maintains a pristine look due to its stain resistance. It is the hallmark of a high-end folder.

Conclusion

The battle of s35vn vs m390 highlights the incredible advancements in modern cutlery. A few decades ago, neither of these steels existed, and knife users were forced to choose between soft stainless steels that wouldn't rust or hard carbon steels that rusted instantly. Today, we are spoiled for choice.

Ultimately, if you choose a knife from CJRB in either of these steels, you are getting a high-performance tool. The heat treatment is the soul of the blade, and consistent, quality heat treatment ensures that whether you pick the tough-as-nails S35VN or the everlasting edge of M390, you will have a reliable companion for years to come.

FAQ: S35VN vs M390

Here are answers to the most common questions regarding these two super steels.

1. Is M390 worth the extra money over S35VN?

For most users, yes, if you prioritize edge retention and low maintenance. If you despise sharpening your knife and want it to stay razor-sharp for as long as possible, the premium for M390 is justified. However, if you are on a budget or enjoy the process of maintaining your tools, S35VN offers incredible performance that is very close to M390 at a better price point.

2. Will S35VN rust easily?

No, S35VN is a stainless steel and is very resistant to rust compared to tool steels like D2 or M4. However, it is not as stainless as M390. If you use S35VN near saltwater or cut acidic fruits (like lemons) and don't wipe it off, you might see some patina or light staining over time. M390 is virtually rust-proof in these scenarios.

3. Can I sharpen M390 with a standard whetstone?

Technically yes, but it will take a very long time and may result in a polished but dull edge if the stone isn't hard enough to cut the vanadium carbides. It is highly recommended to use diamond plates or high-quality ceramic stones for M390. Standard Arkansas stones or cheap hardware store sharpening pucks will struggle effectively against M390.

4. Which steel is better for a heavy-duty survival knife?

S35VN is generally the better choice for a large survival knife or fixed blade. In survival situations, blade failure (chipping or snapping) is catastrophic. S35VN's superior toughness ensures the blade stays intact during chopping or batoning. M390 is better suited for slicing tasks in folding knives rather than high-impact tasks in fixed blades.

5. Is S35VN obsolete now that S45VN and MagnaCut exist?

Absolutely not. While newer steels continue to push the envelope, S35VN remains one of the most balanced and proven steels in history. It is widely available, affordable, and its performance characteristics are well-understood by makers and users alike. It remains a "Gold Standard" for a reason—it works exceptionally well for 99% of users.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.